But what technologies actually help beat competitors? How is the oil and gas industry doing in 2021? Based on our customers’ experience, we’ve made a list of top opportunities to seize with IT tools this year.

Digitalization — a silver bullet for the future of oil and gas

The O&G industry is always chaotic. However, the next post-pandemic decade will be very different for this market as the downturn has accelerated such oil and gas industry trends as decarbonization and digital transformation (DT). For instance, IDC forecasts global investments in DT to reach $2.3 trillion by 2023.

The last year’s disruptions proved that business and DT strategies are inseparable even in the O&G field. Progressive C-suites now consider enterprise digitalization as imperative, and choosing the right technologies is essential as they enable organizational flexibility and resiliency.

The strategic value of digital technologies

Speaking from our experience, IoT, AI, ML, and remote monitoring solutions have already helped dozens of our O&G customers. Areas of improvement include numerous aspects, from better operational efficiency and labor safety to reduced downtime and overall costs.

Digitalization covers numerous business goals for oil and gas organizations:

- Enabling productive remote operations and human-machine collaboration

- Minimizing and managing both cybersecurity and on-premise risks

- Improving recovery and sustainability rates

- Setting emissions targets and extending life of existing assets

- Increasing enterprise adaptability to future disruptions

It’s safe to say, companies that are bold enough to use this crisis as a catalyst to restructure their operating models with digital technologies will beat the current humanitarian and economic challenges. O&G executives should be aware of oil and gas industry trends and turn to the IT field to meet consumer expectations, safeguard their workforce, and secure better outcomes. Digital is critical for survival now more than ever.

What oil and gas technology trends will dominate the industry in 2021

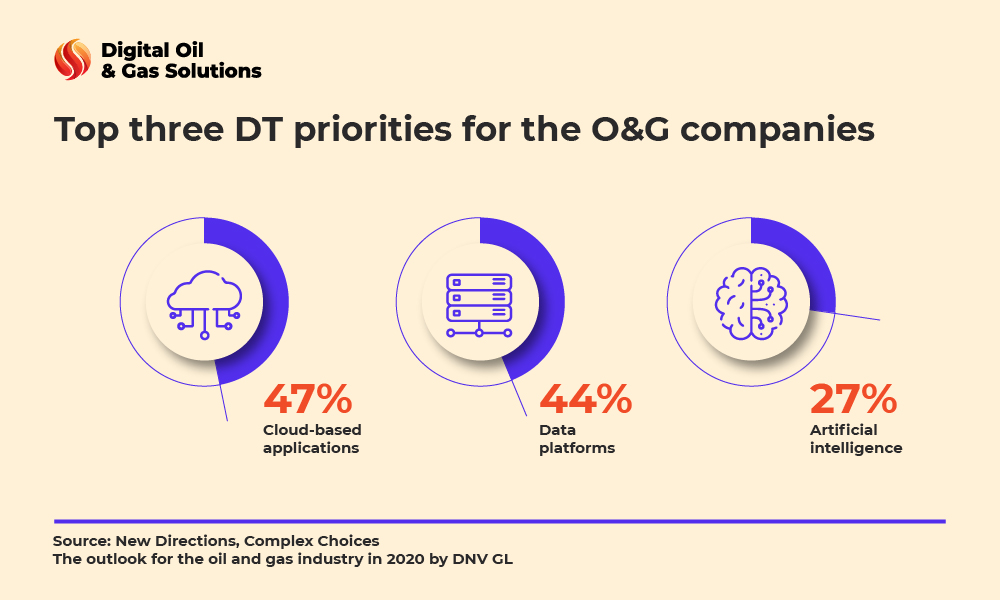

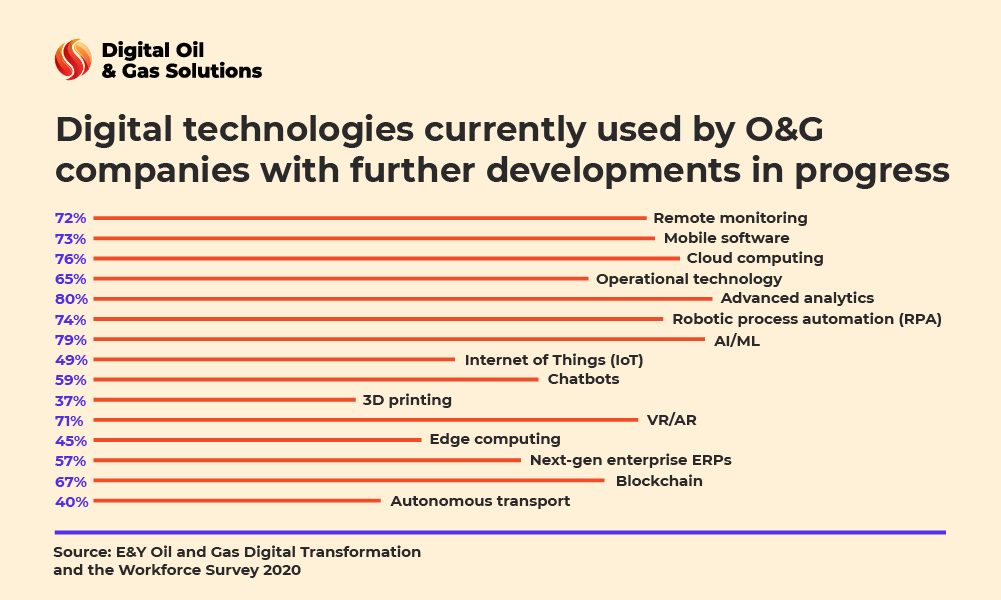

Ernst & Young revealed that, during the next decade, 90 percent of industry leaders plan to increase their investments in the following areas:

Based on the survey data, respondents confirm that DT strategies adopted by their companies focus on software that covers:

- Client and workforce management

- Document processing and analytics

- Cloud computing and assets virtualization

- Trade and risk management

- Enterprise resource planning

- Legacy systems modernization

- And more

Hence, digital technologies have proven to bring positive results across the energy field. Below are seven oil and gas industry trends that we believe will dominate the market in 2021, enabling business continuity and improving customer and employee experience.

IoT for well and reservoir management

Innovative vendors create IoT-based production optimization models that help lower operating costs, maximize ROI, and increase productivity. Such models combine the power of cloud computing, AI, ML, digital field data capture, and limitless virtual storage. There is a good reason why this technology tops the list of oil and gas industry trends for this year.

IoT sensors and other interconnected devices networked with management software allow you to process vast amounts of data regarding the status of your assets in seconds. You can monitor such parameters as gas lift, pressure, injection, waterflood, leakage alerts, and more. IoT tools also give operators data-driven recommendations on preventative maintenance and well and reservoir usage optimization. As a result, your company can reduce downtimes associated with equipment replacement.

The most important benefit of this trend is that you don’t have to develop such products from scratch. The IT market already offers fully ready for use well monitoring systems. Platforms like Scada Lite, for example, process real-time data from your assets 24/7, ensuring cost-efficient, smart oil and gas operations.

3D printing to speed up production and field management

Versatile additive manufacturing erases barriers prompted by lockdowns as you can now, for example, print the needed spares kits or prototype new parts on-site at any time. 3D printing shortens the supply chain cycle, making it more resilient, and enforces well-timed maintenance. All these benefits make it one of the leading technology trends in oil and gas industry. However, legal conditions state that industry regulators must first approve a 3D printed part for field usage.

I, robot: digital contingent workers that reduce risks for humans

Aside from automating repetitive and time-consuming operations management tasks, robotics is also being used in drill pipes, wastewater disposal, and industrial machinery repairing. As robots secured their place in the oil and gas trends list and became much more affordable, O&G organizations started using them to cut labor costs and corporate overhead, observe social distancing, and speed up work.

For instance, Norwegian O&G company Aker BP has deployed the quadruped robotic dog Spot, drones, and other mobile robots to pioneer a remotely controlled offshore mission. The goal is to optimize distributed operations and improve a production vessel’s safety and sustainability in the Skarv oil field. Sensor-equipped Spot will be patrolling Aker BP’s O&G offshore facility to run inspections, enhance quality, detect leaks, capture data, and generate automated reports.

Digital twin to rule them all

Simulating real-world conditions in a virtual space, digital twins visualize collected data about assets’ behavior, operations, outcomes, and irregularities. Thus, they enable predictive maintenance, risk mitigation, timely analytics, process optimization, and remote monitoring of your O&G rigs. By implementing this model, you can immediately change the production strategy, making it relevant to the current market demand and preventing revenue loss. All this makes digital twin technology not only one of the main oil and gas industry trends but also a strategic pathway for other business sectors.

4D seismic imaging for improving reservoir monitoring and analysis

Along with augmented and virtual reality, 4D seismic data analysis provides invaluable insights regarding potential exploration fields, helping to drill more effective wells. The 4D method allows detecting changes faster and gaining insights into the spatial movement of fluids over time, making it one of the next-gen oil and gas industry trends. In turn, you can extend the life of hydrocarbon fields and improve the recovery rate, significantly saving the budget.

Data analytics for unlocking new horizons

For strategic decision-making in oil and gas companies that generate vast amounts of data, having digitally-enabled data analysis is essential during any crisis. Advanced Big Data analytics tools eliminate data silos and provide quick and secure access to crucial maintenance and utility data, paving the way to robust risk management.

Real-time, AI-based predictive analytics allow you to forecast a probability of failure for some equipment and identify weak spots in the supply chain. Therefore, you’ll address major problems facing oil and gas industry in 2021, namely decrease maintenance activities and critical equipment downtime drastically, avoiding project delays. With digital instruments, your operators will also improve preparations and planning as they won’t need to search, analyze, and validate all data manually.

Wearables and on-site health monitoring

One of the biggest concerns for O&G executives is ensuring on-premise employees’ well-being and safety by using various wearables. With that said, it is hardly surprising that personal gadgets make our oil and gas industry trends list. In particular, AR and VR headsets help conduct virtual monitoring of dangerous production areas without physically visiting them. What’s more, there are also on-site smart devices like sensors, cameras, control systems, germ-killing robots, and others. With them, you can enhance operations security, inspect air quality, complete risk assessments, track social distancing, and measure employee vitals.

Prosper in the crisis: steps for O&G executives to take

DT is critical for companies that want to move forward in such fields as well and land management, planning and monitoring, drilling and extraction.

Some recommendations for O&G top management to benefit from these oil and gas trends and stay ahead of the curve can include the following:

- Embrace agile models and next-generation practices in all operational areas

- Future-proof business by integrating technologies into appropriate value chain segments

- Remove organizational and cultural challenges halting DT

- Invest in staff upskilling, reskilling, and training to simplify their journey through digitalization

- Establish high-quality data live-stream to track assets conditions

- Outsource strategic partnerships to IT service providers

We’re witnessing a historic collaboration of humans and machines that work in sync to solve immense industry problems. The current global situation requires O&G representatives to take bold actions, striving for resilient delivery, innovations, and operational scalability. However, business leaders should also embrace the crisis as a chance to create new, tailored strategies and thrive. It’s now up to you to lead or to follow.

As experts in IT solutions for the oil and gas industry, we know how hard a digital business transformation can be. So, if you have any questions or want to discuss your project, our experts will be happy to provide a free consultation.