The part the O&G industry plays in reaching the net zero emissions goal

Obviously, the Paris Agreement can’t remain on paper anymore, and the oil and gas industry has to play its part in the global goal. The industry’s operations are responsible for 9 percent of all human-made greenhouse gas emissions. In addition, it produces fuels that create another 33 percent of global emissions. With such a significant environmental impact on its record, the oil & gas industry can contribute to the international net zero goal on an equally large scale. And innovative technologies are the number one ally in this.

What we want to emphasize is that technologies can not only help you achieve the goal but also keep your businesses afloat. The truth is that the world will need less oil and gas in the future. According to IEA predictions, global demand will decline from 90m to about 24m barrels a day by 2050, reducing oil investment. This leaves no chances for new development. To stay profitable, industry leaders need to make existing sites more cost-efficient. Let’s see how you can combine environmental goals and business profitability.

Top 5 innovative technologies to implement as a part of decarbonization plan

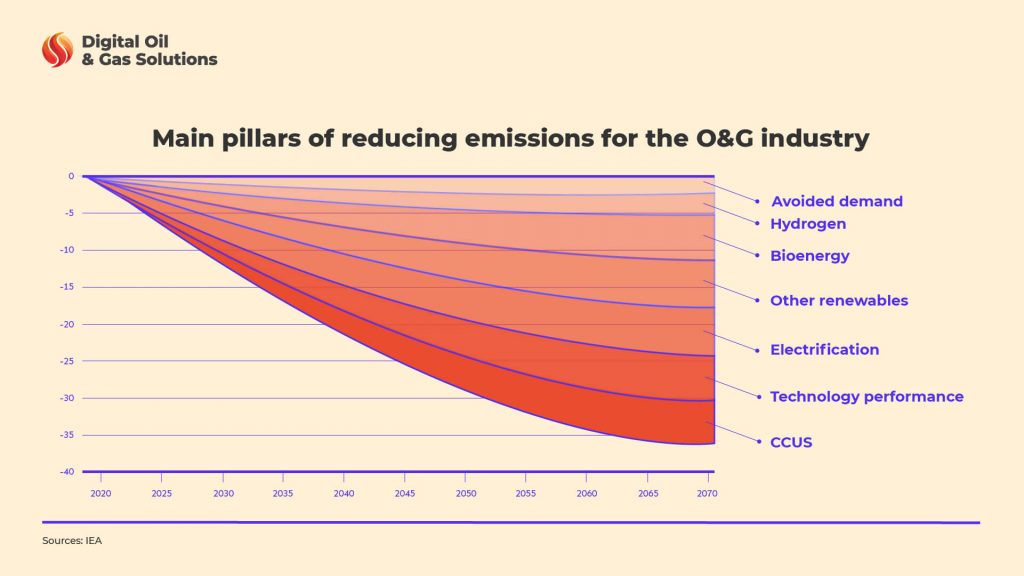

Here’s a great paradox of our civilization: we have been accumulating environmental damage during the industrial era, but the technologies invented at that very period can now help us make up for this damage. According to IEA, renewable energy sources and more efficient field operations are the keys to reaching net zero.

The industry needs additional technologies to make a smooth transition to net zero and stick to these recommendations. The following are expected to have the most impact on this war for the environment.

IoT to monitor field assets remotely

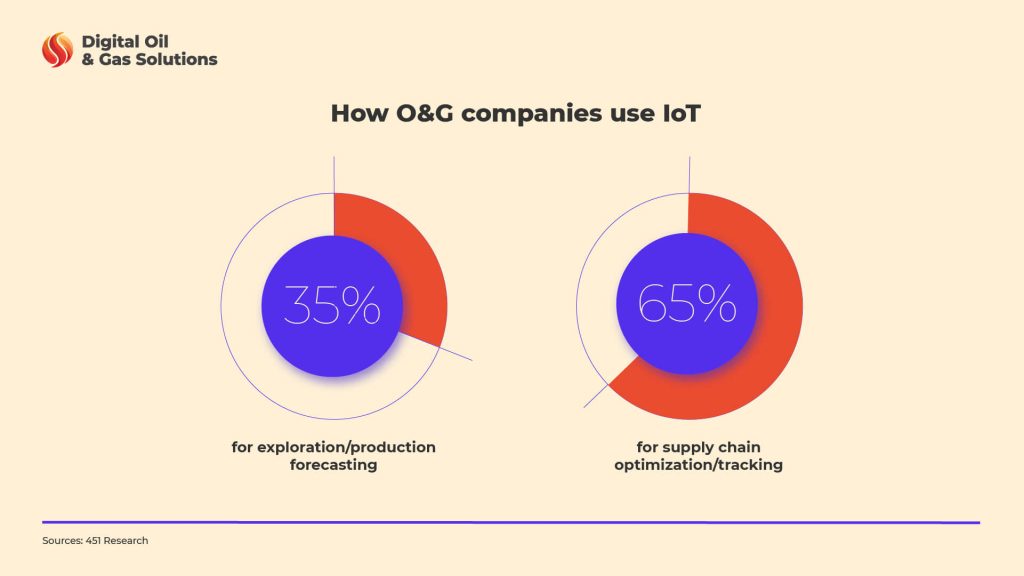

Connecting smart sensors to field assets is the major step oil and gas companies take on their way to digital transformation. It unlocks a new level of operation as there’s no more need for regular physical visits. Asset data becomes available 24/7 leading to better awareness and giving a huge power to reach net zero. Here are the primary IoT use cases that directly correlate with environmental goals:

- Wise energy management. Thanks to connectivity, organizations can continuously track the state of assets and evaluate their performance. This helps calculate how much energy they need to produce and cut the energy supply for unproductive time, which is important for reaching net zero.

- Less leakage-resulting incidents. Connected sensors can quickly detect emergencies and effectively prevent them through alerting on machinery malfunctions. In this way, equipment repairs can be conducted before any failures occur. Consequently, industry leaders can reduce the number of incidents that put personnel in danger and lead to unintended emissions.

- Supply chain optimization. Connected sensors can be used in downstream operations to plan and track consumption that approaches net zero emissions. They show oil levels in real time and check whether there’s a need for a refill. Based on historical data from these sensors, providers can optimize supply time to ensure they don’t waste any additional resources and reduce oil investment.

AI to optimize processes

According to a recent report by PWC and Microsoft, AI has the potential to reduce global greenhouse emissions by 1.5-4 percent during the next twenty years and drive the net zero goal closer. This technology is like a wise counselor that has an even better view of the oil & gas field than we do and knows how to manage it more carefully. Not to mention that the predictive capabilities of AI can’t be compared to those we have.

To make it more specific, let’s see where we can use AI:

- Prediction of potential carbon emissions from a particular field and taking timely measures to optimize operation to prevent them.

- Analysis of the oil-producing potential of already existing fields. This reduces the number of wells that need to be drilled and stops new development.

- CO₂ storage optimization. The gas can be stored underground instead of being released into the atmosphere. At this point, the industry can contribute to CCUS (carbon capture, use, and storage) program and implement enhanced oil recovery that produces less intensive emissions.

AI technology allows taking these vital decisions from anywhere despite vast distances and instantly implementing them across the organization.

Automation to replace manpower

The spread of remote monitoring solutions enables automating some maintenance-related activities. As more and more sites can be operated remotely, field workers are not supposed to visit them every three or four days. This saves driving time, therefore reducing transport emissions.

Second, unmanned sites need less energy as there’s no need to maintain light and air conditions suitable for humans. As a result, such sites consume less energy and generally decrease the level of emissions released while producing it. The same applies to the automation of paper-based processes; when they are performed by robots, employees spend less time on facilities and save power. Altogether, investing in oil assets automation allows cutting operational costs in the long run and reaching net zero emissions faster.

Digital twin to improve decision-making

A digital twin is a technology that creates a virtual replica of your assets. It gives faster access to real-time data and provides more detailed data. For 2021, digital twins are among the oil and gas industry’s top 10 digital spending priorities. Such innovative technologies are relatively young for the industry: the first provider that participated in such a project was Royal Dutch Shell (collaboration with Akselos and LICengineering in 2017).

The main benefit of digital twin technology is that it creates detailed visual simulations and combines them with big data analytics. Such a combination enables structural integrity management of selected assets. This allows testing alternative engineering solutions that extend the life of field assets. A digital twin is one of the best oil investments as it helps get more from existing sites instead of starting new development (which would contradict the Paris Agreement and the net zero goals).

Alternative power technologies to reduce fuel burning

Any optimization won’t make that much difference if oil & gas companies continue running equipment on gas and diesel. Electrification is the universal way to cut emissions. Therefore, conscious providers like Norwegian Continental Shelf and UK Continental Shelf have already committed to the electrification of their fields in the next two years to reach net zero as soon as possible.

Moreover, the energy used in field operations can be produced from renewable sources. Deloitte survey found out that 31 percent of O&G executives emphasize the integration of renewable energy sources into their operations. As International Energy Agency has highlighted, it’s a foundation for reaching net zero emissions. Solar photovoltaic, wave and wind power technologies are evolving fast enough to make this happen. Once renewables are implemented, and AI-based algorithms are put in charge of the energy distribution, its usage is going to decrease throughout the whole value chain.

Final thoughts

You, as an oil & gas industry leader, will benefit once you start taking net zero commitments not as restrictions but as opportunities to build more efficient processes. With the help of IoT, AI, automation, digital twin, and other innovative technologies, it becomes easier to make timely business decisions that can instantly transform the way your field operates. Tailored solutions allow adjusting these technologies to the needs of your particular company. As a result, you only win by contributing to a better ecological future and building a sustainable business without new development as required by the International Energy Agency.