As a result, today’s generic digital twin architecture (GDTA) has new dimensions and use cases that companies can benefit from.

The value of digital twins for oil and gas companies

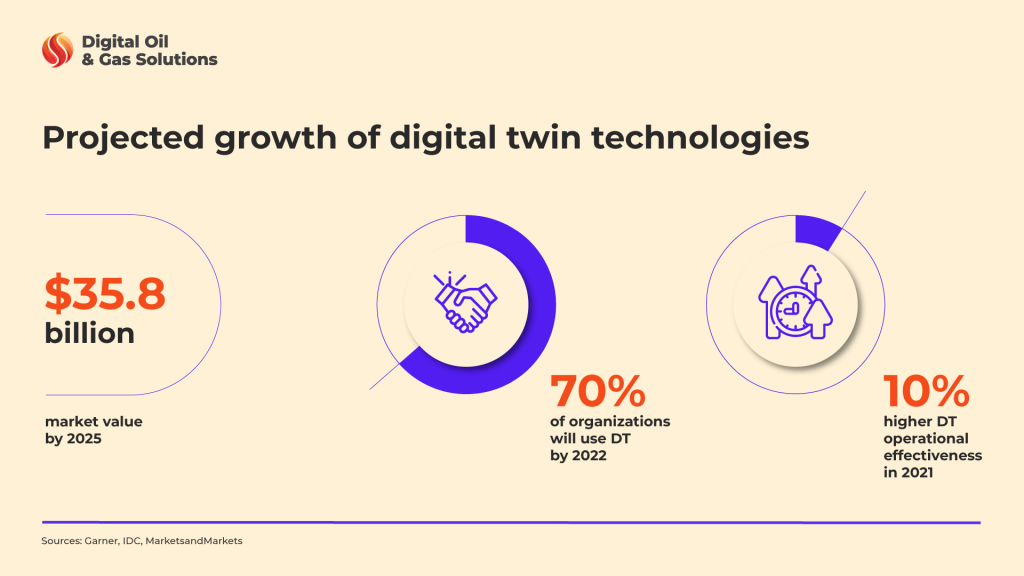

For the oil and gas industry, digital twins have opened the way for predictive maintenance of field assets thanks to the integration of smart sensors and data processing capabilities. This is a huge step towards cost-efficiency, employee safety, and reaching net-zero goals. Digital twins have the potential to increase operational effectiveness of oil and gas organizations by 10 percent.

Some companies use DT technology for interactive employee training. This digital twin example (pictured below) created by Digital Twin Studios presents a safety training solution for field workers that simulates emergency situations. The program aims to ensure that employees are prepared for various scenarios such as administering first aid, managing power tool safety, and dealing with hurricanes in near-real circumstances.

Also, digital twins are a part of approaching Industry 4.0 that presupposes implementation of connectivity, analytics, human-machine interaction, and advanced engineering across the value chain. Better process orchestration and environmental consciousness are the focus of this formation, and digital twins can play a pivotal role in such a transition. This is achievable through the architectural and technological improvements described in this article.

The evolution of digital twins

Architecture

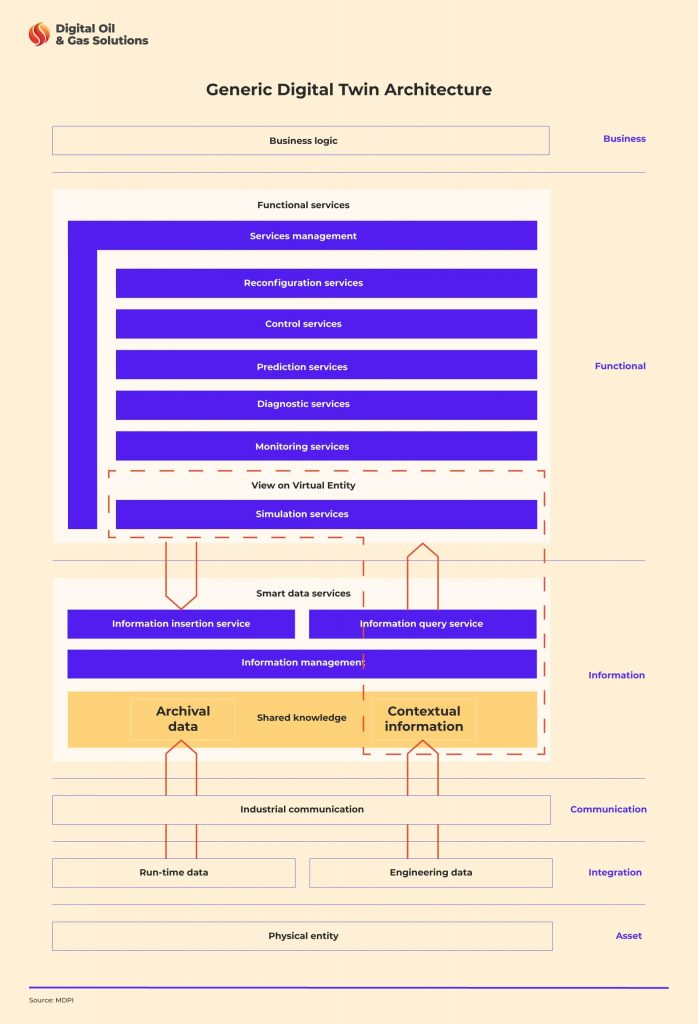

A digital twin is a bright representation of a Cyber-Physical System concept as a substance that operates within all production levels to ensure their cooperation. The ability to collect and process data is a prerequisite for a CPS to monitor processes and tasks in the value chain. Likewise, their virtual replicas must be available. Therefore, basic digital twin architecture consists of the physical entity, its virtual representation, and a connection between them to enable data exchange.

This structure was extended, though, with more functional capabilities in mind, and the five-dimensional digital twin came to be: through adding service aspect and data aspect to the initial model. The role of the former is to optimize operations of the physical entity and the accuracy of its representation by the virtual entity. Meanwhile, the second aspect is about the fusion of the data from a physical entity, its virtual entity, and its services.

This structure has become a basis of the generic digital twin architecture developed in alignment with the Reference Architecture Model Industry 4.0 (RAMI4.0). The primary value of this model is that it is not application-specific, and can therefore be applied to different industries. Based on GDTA, you can build a digital twin within any existing framework or technology.

The model introduces the RAMI4.0 layers to the industrial infrastructure. These layers are supposed to meet the conditions of Industry 4.0 and take control of the value chain. In such a context, a digital twin architecture includes:

- collecting data from physical assets

- processing it with IIoT protocols

- making it meaningful through enriched contexts

- delivering industry-specific services

- meeting overall business objectives

GDTA can be applied to oil and gas companies to optimize the value chain and ensure interoperability of a digital twin, IoT, and data management.

Supporting technologies

The architectural evolution of digital twins is one side of the coin that deals with frameworks and processes. Meanwhile, technologies are developing simultaneously that unleash the new capabilities of a digital twin:

- New data sources. As asset monitoring equipment evolves, more data becomes available in real-time. Such technologies as LIDAR (light detection and ranging) and FLIR (forward-looking infrared) can be used to create digital twin simulations. Moreover, embedding smart sensors at various levels of the value chain can make these simulations complete and provide comprehensive data on a 24/7 basis.

- Visualization tools. The level of visualization technologies used to be a bottleneck for creating meaningful digital twin simulations. But not anymore: today’s tools include interactive 3D, VR and AR-based visualizations, and real-time streaming. All of these make work with digital simulations more productive and more accessible.

- Instrumentation. The evolution of IoT sensors, which are becoming both smaller and cheaper, leads to better integration with virtual models and more accurate data representation. In this way, digital twin software provides viable data for timely business decisions.

- Cloud-based platforms. The current trends in cloud computing allow building connectivity platforms that streamline creating digital twins, guarantee interoperability, and improvements in data management and analytics.

Where to start while implementing digital twin technology

As you can see, digital twin architecture opens a wide range of opportunities. The question is how to tailor them to your company. We suggest taking the following steps:

- Map the benefits. It’s advisable to create a list of use cases and scenarios of DT implementation and assess which of them provide the most value.

- Identify the pilot configuration. This includes analysis of operational, business, and organizational change management factors and focusing on value chain areas that have scaling potential.

- Launch a pilot. Ensure its adaptability and integration, establish a clear framework to estimate its efficiency and make technological or operational amendments.

- Industrialize the pilot. Make the initial project more mature by managing expectations, improving data standards, and making changes within the organization to support the digital twin.

- Scale the solution. When you see the pilot is successful, it’s time to expand the digital twin by implementing it to the areas and processes adjacent to the pilot. Previously developed frameworks and techniques can be applied at scale to ensure streamlined integration.

- Monitor the value. Once the digital twin is integrated into your value chain, prepare checklists for continuous monitoring of its performance and calculating the value it brings to the business. This will help timely optimize the technology and leverage it to its maximum potential during its whole life cycle.

Closing thoughts

The concept of GDTA has opened new opportunities for oil and gas companies to optimize their value chain and approach Industry 4.0. However, the process of building this architecture involves all operational and technological levels. Therefore, the support of digital experts is needed to ensure that implementation of a digital twin is efficient and valuable.